How to use the Cosmetics Lab Soap Calculator

To make soap using the cold process method, you’ll need to mix specific fats or oils with lye (also known as caustic soda) following a precise procedure.

The Cosmetics Lab Soap Calculator is a user-friendly tool that helps you determine the exact amounts of each ingredient by making precise calculations of proportions, ensuring reliable results every time.

In this tutorial, we’ll walk you through how to use its features to confidently craft your own custom soap recipes!

Prefer watching instead of reading?

Both videos demonstrate the Cosmetics Lab Soap Calculator step-by-step.Contents at a Glance

Below is a quick overview of the topics covered in this guide. Click on any of the links to jump directly to the corresponding section:

- Introduction

- Detailed explanations at every stage

- Recipe builder modes

- Navigating through wizard steps

- Bars of soap or liquid soap?

- Water: how much?

- "Masterbatch" and lye

- Amounts of fats and oils

- Superfatting

- Selecting fats and oils

- Using the sortable oil list to select oils and fats

- Essential oils, fragrances, herbs and other additives

- Ingredients requiring special handling

- Adding a recipe title and notes

- Uploading an image for your recipe

- Viewing the recipe results

- Viewing ingredient INCI names

- Saving a recipe

- Creating a template from current recipe

- Printing your recipe

- Managing your recipes

- Using QR codes

Introduction

If you’re new to cold process soap making, I recommend reading a tutorial about cold process soap making.

Once you’re familiar with the basics, here’s what you’ll need to do next:

- Choose the fats or oils for your recipe. This decision depends on the properties you want your soap to have (e.g., conditioning, lathering) and is largely a matter of personal preference.

- Set other parameters, such as the amount of water, superfatting percentage, and total batch size.

The Soap Calculator allows you to set or select all the above parameters through clear, user-friendly steps.

Note: If you’re ever unsure about which value to select, simply use the suggested default value.

Detailed explanations at every stage

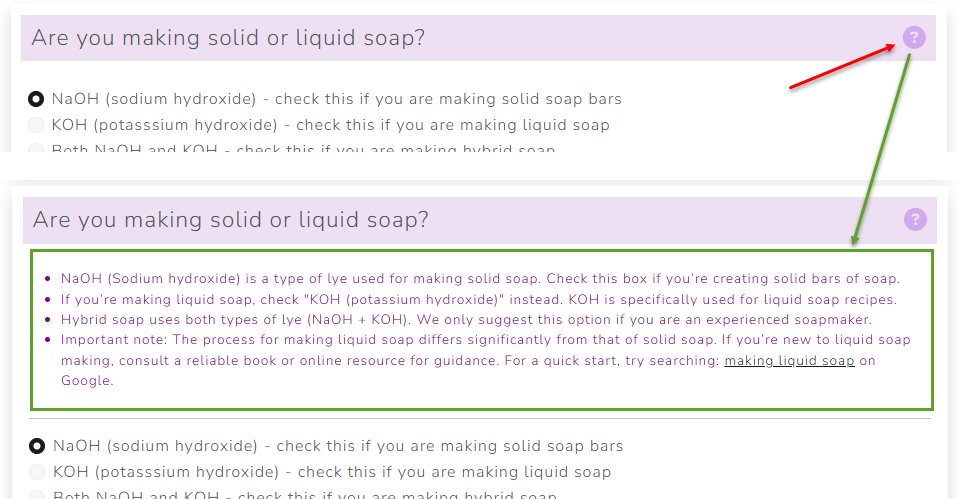

If you need help or an explanation at any stage, you can

- Click in the card header. This will expand a section with detailed information about the current step.

- Click the "?" icon at the top right of each card. This will open another window and take you to the related section of this document.

To collapse an expanded information section, click the card header again.

Note: in Simple wizard mode, the help sections are already expanded for your convenience.

Recipe builder modes

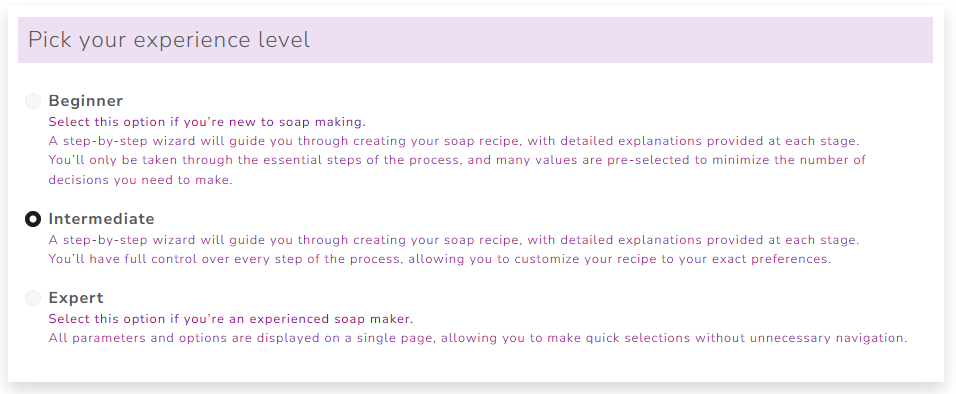

To cater to different levels of expertise in soap making, the Cosmetics Lab Soap Calculator offers three distinct user interfaces.

- "Simple Wizard": If you’re new to soap making, select this option. A step-by-step wizard will guide you through the process, providing detailed explanations at each stage. Many values are pre-selected to minimize the number of decisions you need to make, making it ideal for those just starting out.

- "Full Wizard": Choose this option if you want full control but still prefer step-by-step guidance. The wizard walks you through the entire recipe setup while letting you customize every parameter to match your preferences.

- "One-Page Mode": all options and parameters are displayed on a single page. This mode is designed for experienced users who prefer quick access and direct editing without extra navigation.

If you want your choice to be remembered next time you use the Soap Calculator, just check 'Remember my selection' before clicking "Next". Please note that you need to be logged in for this to work.

Navigating through wizard steps

If using the step-by-step wizard (Simple Wizard or Full Wizard mode), click buttons Next/Back to move between steps.

IMPORTANT: Do not use your browser's "Back" button to navigate to the previous step.

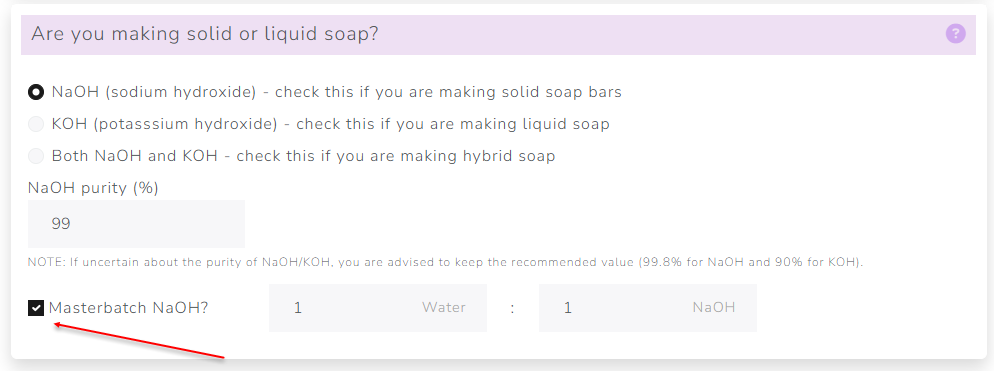

Bars of soap or liquid soap?

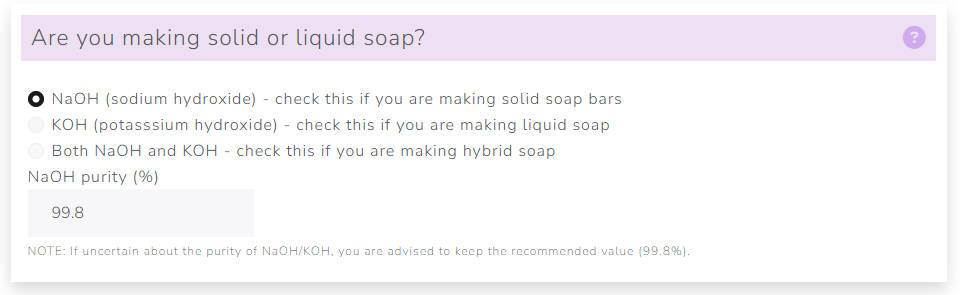

- If making bars of soap, select "NaOH".

- If making liquid soap, select "KOH".

Note: In the "Simple Wizard" wizard mode, this step is omitted. It is assumed that you'll be making bars of soap.

NaOH/KOH purity:

- This refers to the purity percentage of your lye, typically ranging between 98% and 100%. Your supplier should provide this information. The purity level is used to calculate the exact amount of lye required for your recipe.

- If you are unsure about the purity of your NaOH or KOH, simply use the recommended default value of 99.8%.

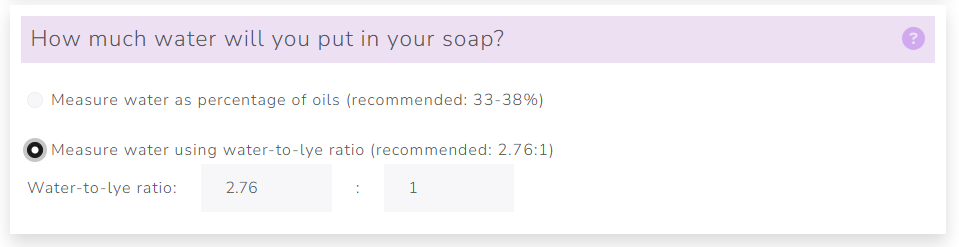

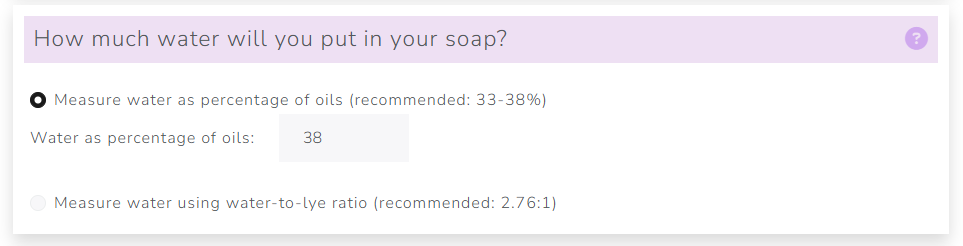

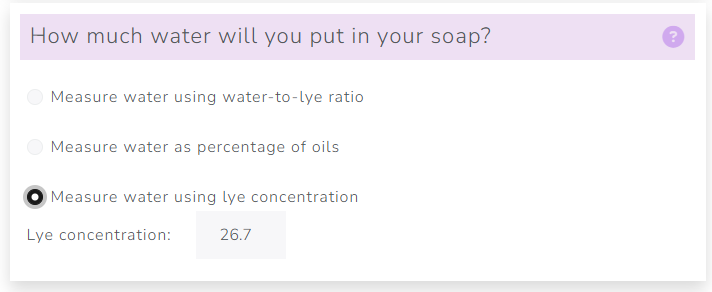

Water: how much?

Note: In the "Simple Wizard" wizard mode, this step is omitted. The amount of water is pre-selected for you.

The amount of water used to dissolve the lye plays a crucial role in the soap-making process. It affects how quickly your soap thickens (reaches "trace"), when you can cut it, how fast it dries (cures), and how hard the finished bar will be.

This amount can be expressed:

- as a water-to-lye ratio (recommended range: 1.7:1 - 2.7:1)

- as a percentage representing the ratio of water to the total weight of oils/fats in the recipe (recommended range: 22% - 34%)

- as a number indicating the lye concentration (recommended range: 27% - 37%)

Note: As [water-to-lye ratio] and [water as percentage of oils] increase, [lye concentration] decreases.

Note: Some soapmakers recommend using much higher lye concentrations - up to 50% (a 1:1 water-to-lye ratio). While this may be suitable for more experienced soapmakers, beginners are advised to stick to the recommended range above. A larger amount of water gives you more time to work with your soap before it reaches trace and is more forgiving if errors or delays occur.

Even for experienced soap makers, a higher water content is recommended when:

- Trying a new recipe for the first time.

- Using a fragrance or essential oil for the first time, as some fragrances/essential oils can accelerate thickening, making it difficult to pour the soap into molds - especially if the water percentage is low.

Things to keep in mind:

- Less water (higher lye concentration) leads to harder soap bars and faster cure, but may sometimes lead to faster trace.

- More water (lower lye concentration) allows for more working time, but results in a longer cure time and potentially softer bars of soap.

"Masterbatch" and lye

In soapmaking, a masterbatch refers to a lye stock solution that you prepare in advance by dissolving NaOH (or KOH) in water. Having this solution ready allows you to measure out what you need quickly when making soap.

If you check the "masterbatch" checkbox:

- You’ll need to enter the water-to-lye concentration of your pre-made solution. A 1:1 ratio is recommended.

- In the recipe results, instead of showing the required weight of pure NaOH, the calculator will display the weight of masterbatch solution to use.

- The calculator will subtract the water already contained in your masterbatch solution, so the water amount shown is exactly what you still need to add to your recipe.

Amounts of fats and oils

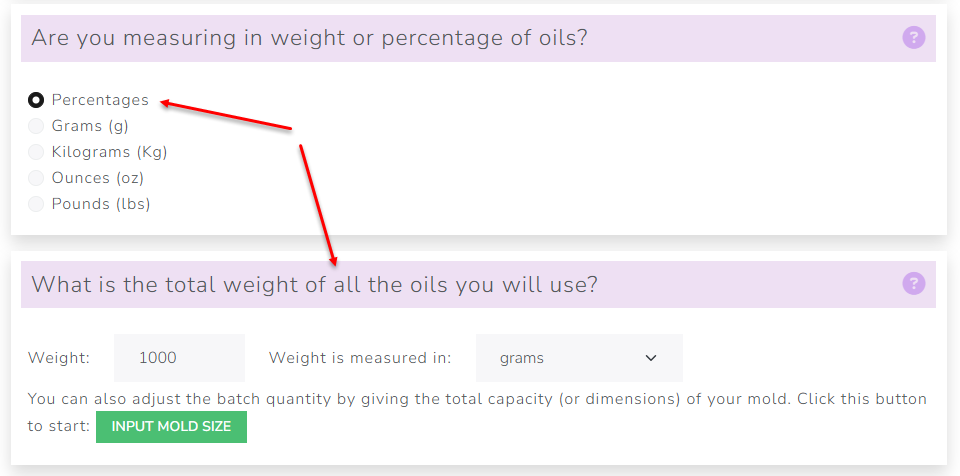

The Soap Calculator requires you to input the amount of each fat or oil in your recipe. There are two ways to do this:

- Specify the total weight of all fats and oils (in your preferred unit, e.g., pounds or grams), and then indicate the amount of each fat/oil as a percentage of the total weight.

- Specify the weight of each individual fat or oil (in your preferred unit, e.g., pounds or grams).

Below we'll explore each scenario in detail.

Scenario 1: Specify the total weight and indicate the percentage of each fat or oil

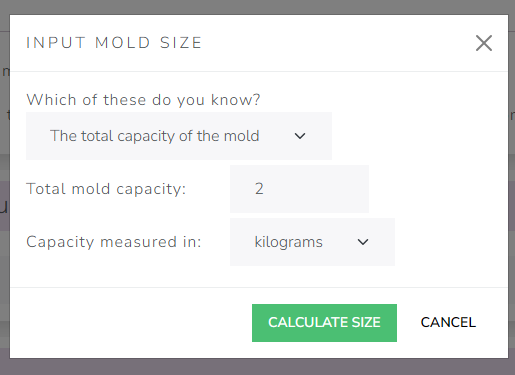

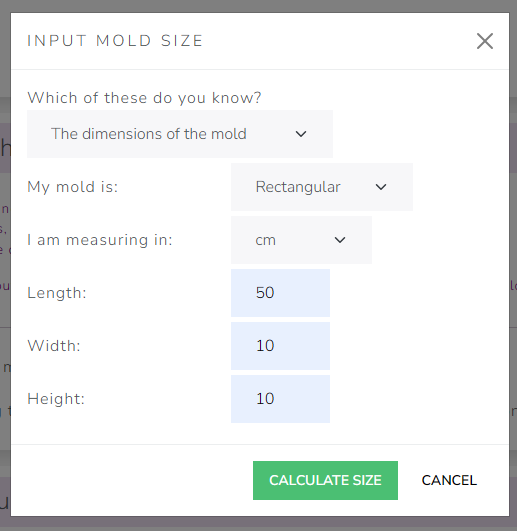

If you're unsure of the total weight of oils to use but you know the dimensions of your mold (or the weight of soap it can hold), click "Input mold size" for assistance in determining the correct amount. In the pop-up window that appears:

-

If you know the total capacity of the mold (e.g. it can hold 2 kilograms of soap), select "The total capacity of the mold" and input the capacity along with your preferred unit of measurement.

-

If you know the dimensions of the mold, select "The dimensions of the mold", specify whether your mold is rectangular or cylindrical, and input the dimensions along with your preferred unit.

- Then, click "Calculate size" and the total weight of the fats/oils will be calculated and filled in the appropriate box for you.

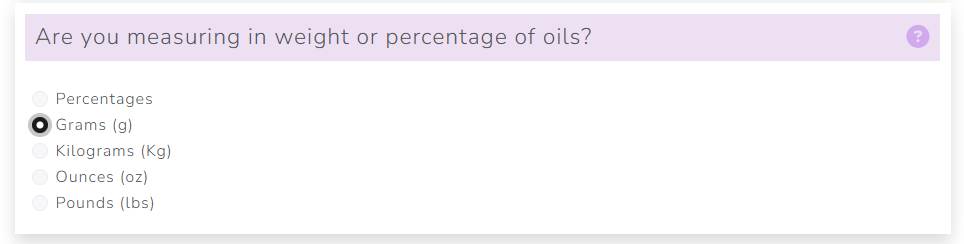

Scenario 2: Specify the weight of each individual fat or oil

In this case, all you need to do at this stage is select your preferred unit of weight. Later, when selecting the fats and oils, you’ll be prompted to input the weight for each one individually.

Superfatting

Note: In the "Simple Wizard" wizard mode, this step is omitted. A default value is pre-selected for you.

If part of the lye does not react with the oils and remains in the soap after the saponification, the resulting soap can be caustic and harsh to the skin. To prevent this, most soapmakers use an excess of oils and fats in their recipes - more than the amount theoretically required to react with the lye. This process is called superfatting. You may also hear the term "Lye discount", which is essentially the same concept.

Superfatting also benefits the skin as the excess of oils in the soap create a protective, moisturizing layer.

Superfatting is expressed as a percentage, typically ranging between 1-10% (with the recommended value around 5%). However, many soapmakers use significantly higher superfatting percentages. Keep in mind that:

- Higher superfatting results in a softer soap and reduces lather production.

- Soaps with higher superfatting are more prone to going rancid over time.

We recommend experimenting with different superfatting percentages to find the right balance for your preferences and needs.

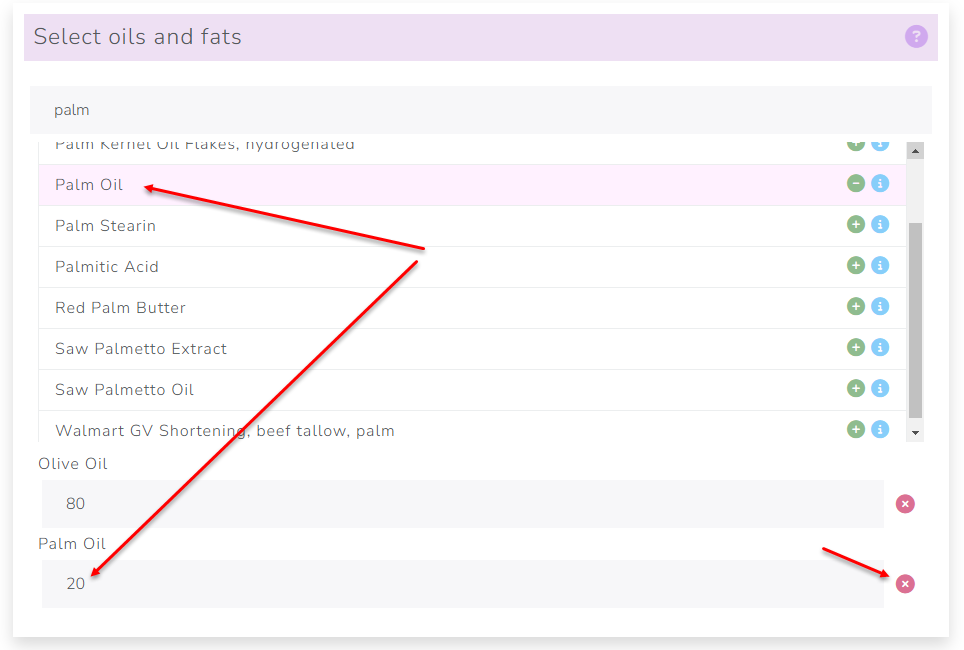

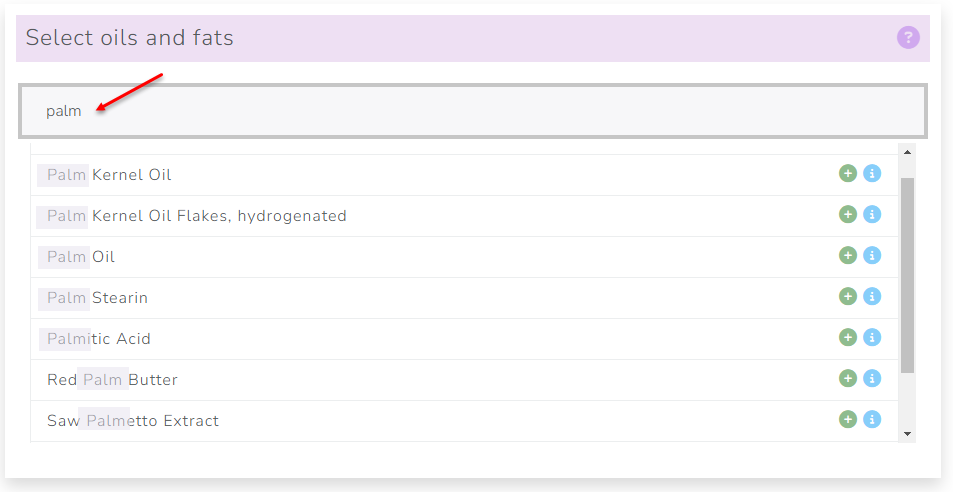

Selecting fats and oils

The fats and oils you choose will determine the properties of your soap, such as lathering, conditioning, creaminess, and more.

To add a fat/oil to your recipe:

- Browse the list,

- or, type a few letters in the search box to filter the list and display fats/oils that match your input.

- Click on the fat/oil you want to select it.

- Enter the percentage (or weight) for this fat/oil in the corresponding text box.

Note: If you’re entering quantities as percentages, ensure that the total sum of all percentages equals 100%.

Selected fats/oils are highlighted with a colored background in the list.

To remove a selected fat/oil:

- Click on it again in the list, or

- Click the "x" button on the right side of the selected fat/oil.

Using the sortable oil list

The fats and oils you choose will determine the properties of your soap, such as lathering, conditioning, creaminess, and more.

To assist you in selecting which oils/fats to use, we have created a sortable oil list.

It lets you easily view, compare, and sort oils by their key soapmaking properties — like hardness, conditioning, bubbly, creamy, longevity, fatty acid profile, etc. — all in one clean, easy-to-scan table.

You can use it to:

- Instantly spot oils with the properties you need

- Compare substitutes side by side before updating a recipe

- Explore new combinations while keeping your recipe balanced

To use it, select any fatty acid / property from the list to sort by it. Or simply click on any column header to sort by that column.

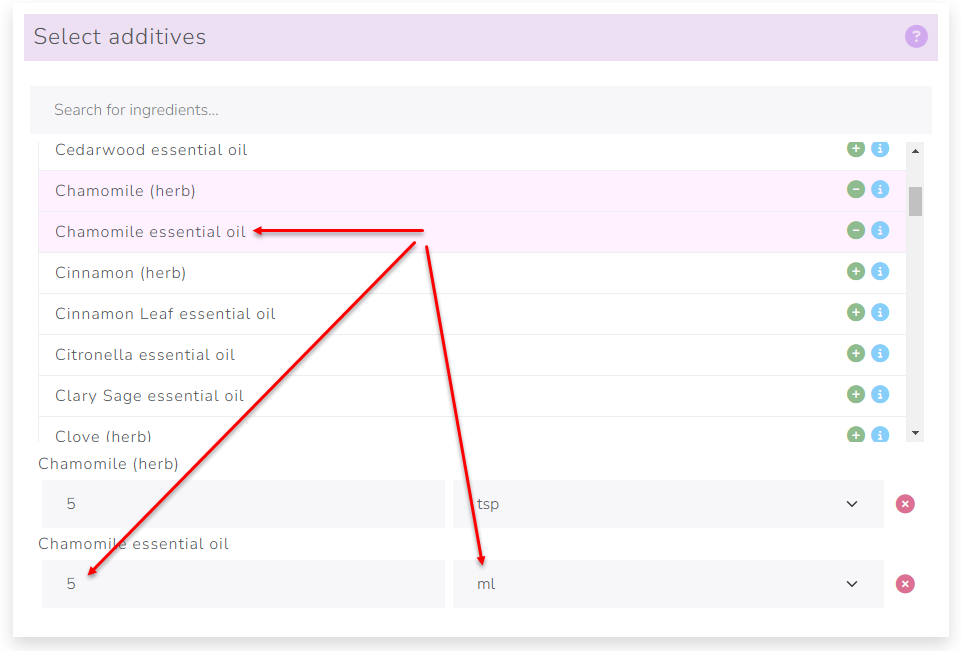

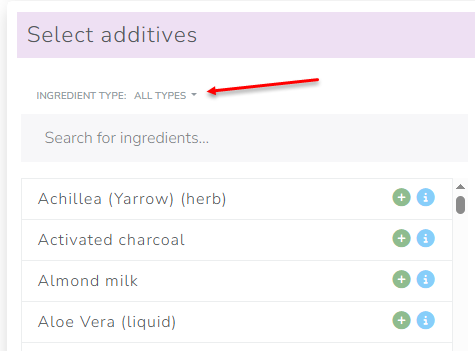

Essential oils, fragrances, herbs and other additives

Optionally, you may want to include additional ingredients, such as fragrances, essential oils, or herbs. For simplicity, I’ll use the collective term "additives" to refer to all these ingredients.

To add an additive to your recipe:

- Browse the list,

- or, type a few letters in the search box to filter the list and display additives that match your input.

- Click on an additive to select it.

- Enter the amount for this additive in the corresponding text box and select your preferred unit (e.g. pounds, ounces, ml, drops).

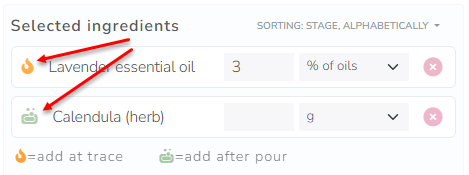

- You can specify the stage at which this additive must be added (with the fats, at trace, etc) by clicking the icon on the left of the additive name.

- Note: selected additives are highlighted with a colored background in the list.

To remove a selected additive:

- Click on it again in the list, or

- Click the "x" button on the right side of the selected additive.

Ordering selected additives:

- You may change the order of selected additives by dragging the items and dropping them at the desired position.

- You may also order them alphabetically / by stage + alphabetically by using the "Sorting:" drop down menu.

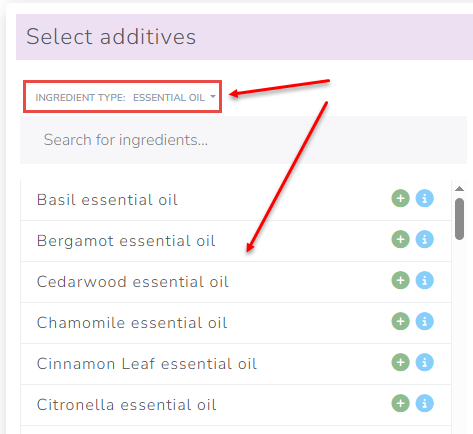

Filtering the list of additives:

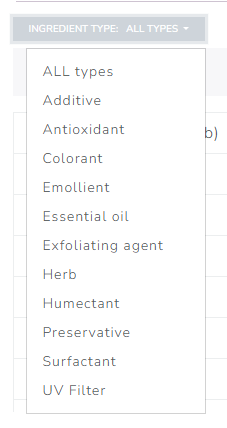

- You may filter the list of additives to only show additives of a particular type (essential oil, herb, etc).

- Click the "ingredient type" dropdown and select the ingredient type. The list will be filtered accordingly.

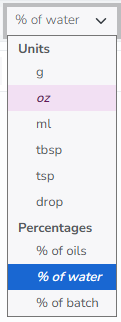

Specifying Measurement Units for the ingredients

Each ingredient can have its own measurement unit for quantity. Available units include:

- Grams

- Ounces

- Milliliters

- Teaspoons

- Tablespoons

- Drops

Alternatively, for certain ingredient types (like essential oils or custom liquids), you can express the amount as a percentage of:

- Total batch weight

- Total oil weight (commonly used for essential oils)

- Total water weight (commonly used for custom liquids like milk or beer)

For example, if you want an ingredient’s amount to be calculated as a percentage of the total water in the recipe and displayed in ounces, follow these steps:

- First, select “oz” from the unit dropdown

- Then, open the dropdown again and choose “% of water”

- You’ll notice that both “oz” and “% of water” are now highlighted in different colors—this indicates that the quantity will be calculated as a percentage of water, but shown in ounces.

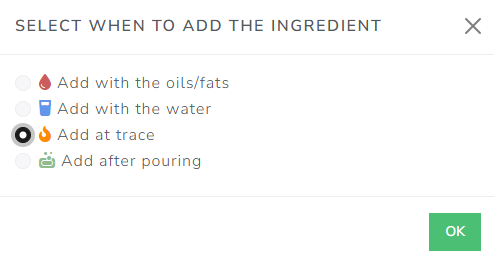

Specifying the stage for a selected additive:

- Each additive should be added at a specific stage (with the oils, with the water, at trace, etc.)

- You may specify the stage for each additive by clicking on the "stage" icon on the left of the additive name.

- In the dialog box that appears, select the stage for the additive and click OK.

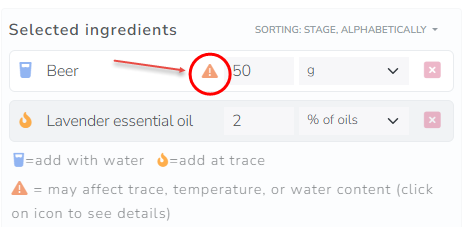

Ingredients requiring special handling

Some ingredients require extra care because they:

- Accelerate trace

- Raise soap temperature

- Affect water handling

Examples include pine tar and custom liquids like milk or beer.

When such an ingredient is added, a warning icon appears next to its quantity.

Clicking this icon opens a popup with:

- Detailed information on how that ingredient affects your recipe

- A checkbox labeled “Apply water discount”

For certain ingredients, this box is checked by default, meaning a water discount is recommended and will be applied unless you choose otherwise.

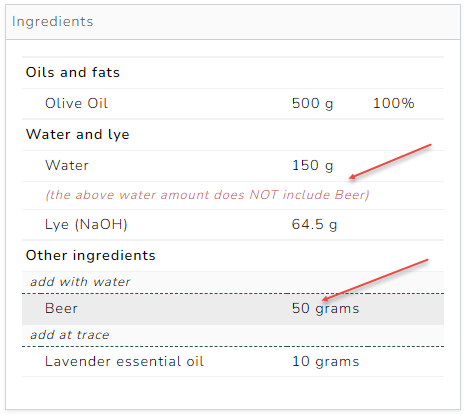

About water discount

Water discount means that in the calculated results, the ingredient’s amount is subtracted from the total water weight.

So, if for example, the total amount of water is 200grams and you add 50grams of beer to your recipe, the total amount of water will be set to (200-50) = 150grams.

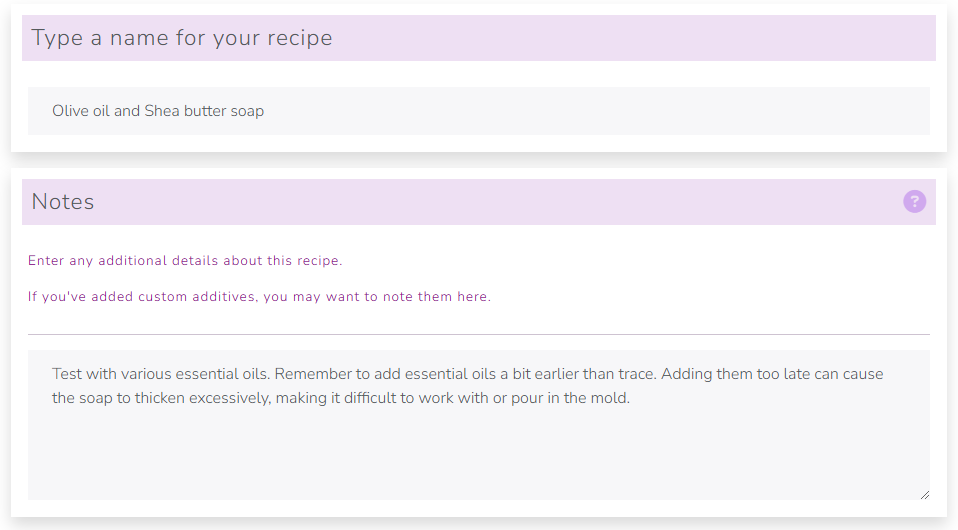

Adding a recipe title and notes

You can name your recipe by entering a title in the appropriate field.

You can also add any additional details about this recipe, such as custom additives you've used or important notes about the process or specific recipe.

Use the 'Notes' field to record this information.

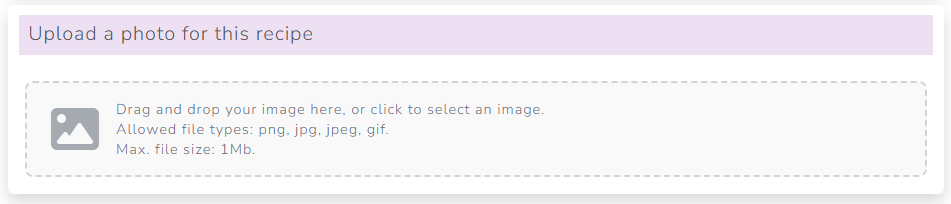

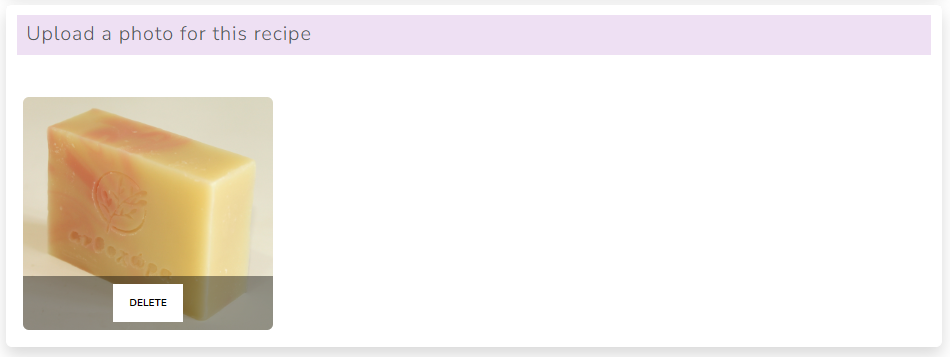

Uploading an image for your recipe

You can upload a photo for your recipe—it’ll show up as a thumbnail next to the recipe name.

To add an image, just drag and drop it into the upload area, or click the area to choose a file from your device.

Supported file types are png, jpg, jpeg, and gif, with a maximum file size of 1MB.

Once uploaded, your image will appear in the preview area.

To remove it, simply click “Delete” and the image will be removed.

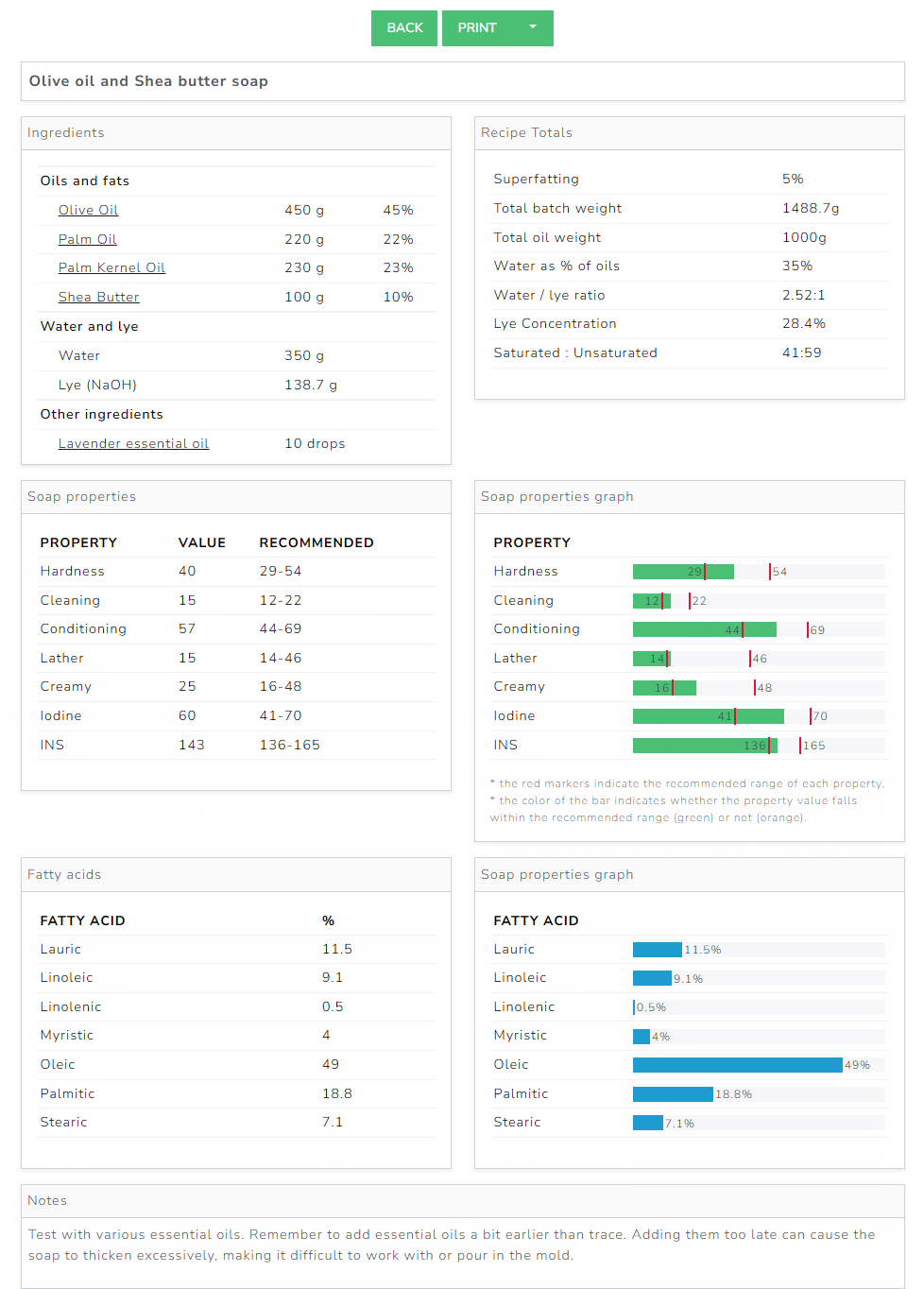

Viewing the recipe results

Once you've made all your selections, the Soap Calculator is ready to generate the results.

Click the 'View Results' button to access a summary of your selections, the calculated amounts, and the title and notes for your recipe.

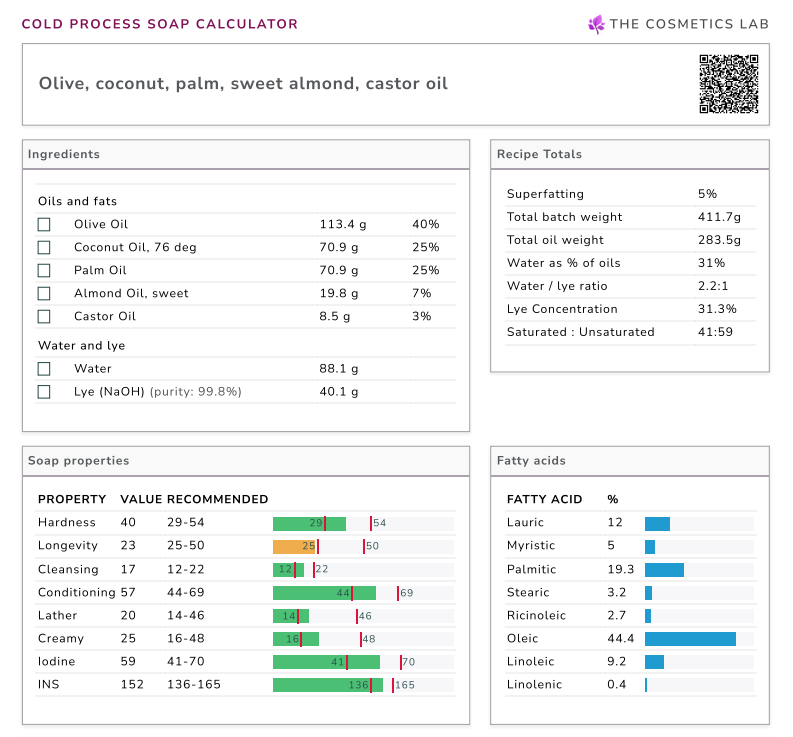

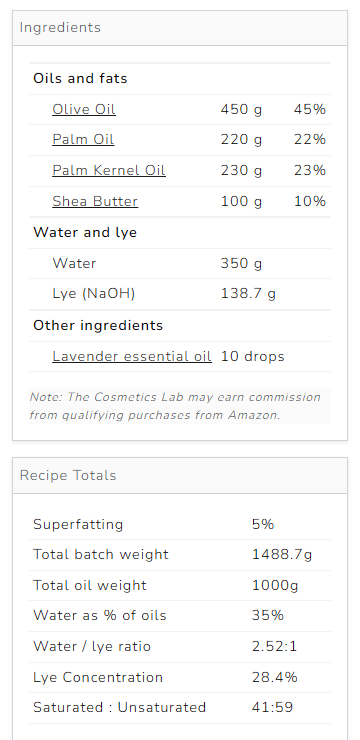

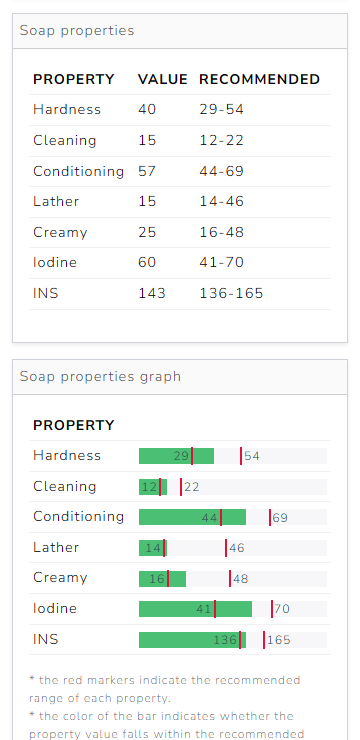

See the image below for a preview of the results page.

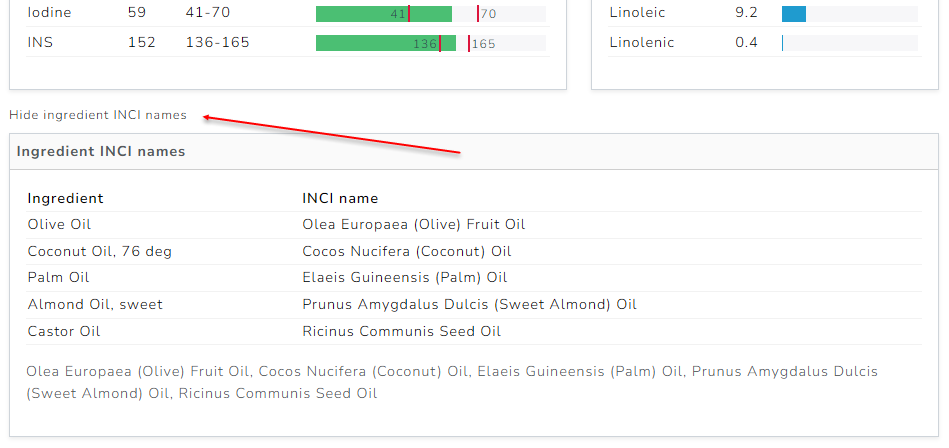

Viewing ingredient INCI names

The Cosmetics Lab Soap Calculator has a convenient feature that lets you view the INCI names of the oils/ingredients in your recipe.

- To see the INCI names, click the link "Show ingredient INCI names" at the bottom left of the results page.

- The card that appears shows a list with all the oils and ingredients along with their INCI names.

- For added convenience, the same list is also displayed as a comma separated text which you can easily copy/paste (for labelling, etc.).

- To hide the list of INCI names, click the "Hide ingredient INCI names" link.

Saving a recipe

NOTE: you need to be logged in to save a recipe.

To save a recipe, just click the "Save" button.

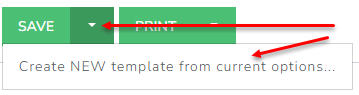

Creating a template from current recipe

NOTE: you need to be logged in to create templates.

You can save the oils, ingredients, and other settings in a recipe as a “template,” allowing you to quickly create new recipes without re-entering everything from scratch.

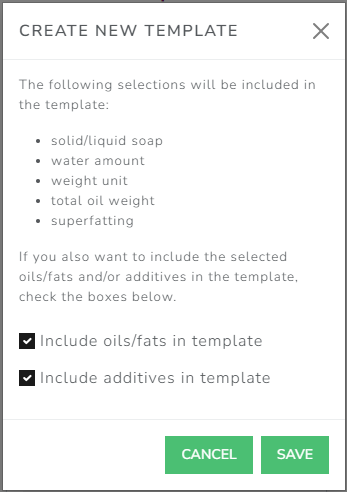

To create a template, click the dropdown arrow next to the “Save” button, then select “Create new template from current options.”

In the popup dialog that appears, you can choose whether to include oils/fats and/or additives in the template.

Finally, click “Save” to close the dialog and save your template.

Printing your recipe

Once you've finalized your soap recipe, click the "Print" button to print it.

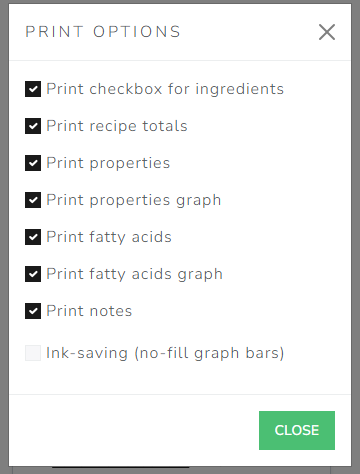

If you click the dropdown arrow next to the "Print" button, you'll see a "Print Options" menu item. Selecting it opens the "Print Options" dialog.

In this dialog, you can choose which elements to include or exclude from printing by checking the appropriate boxes.

If you want your choices to be remembered next time you use the Soap Calculator, just check 'Remember settings' before clicking "Close".

Please note that you need to be logged in for this to work.

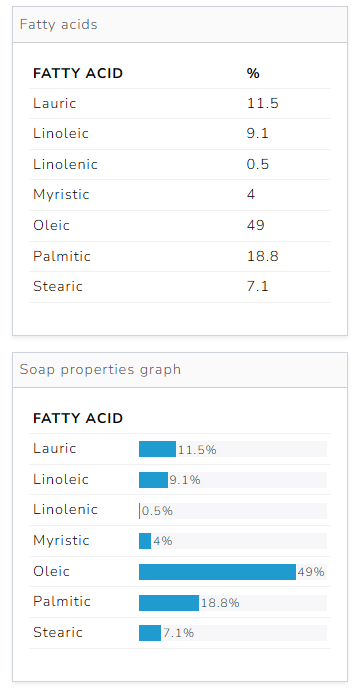

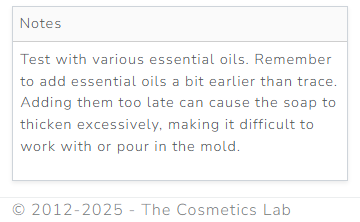

You'll also find an "Ink Saving Mode" option, which significantly reduces ink or toner usage when printing graph bars.

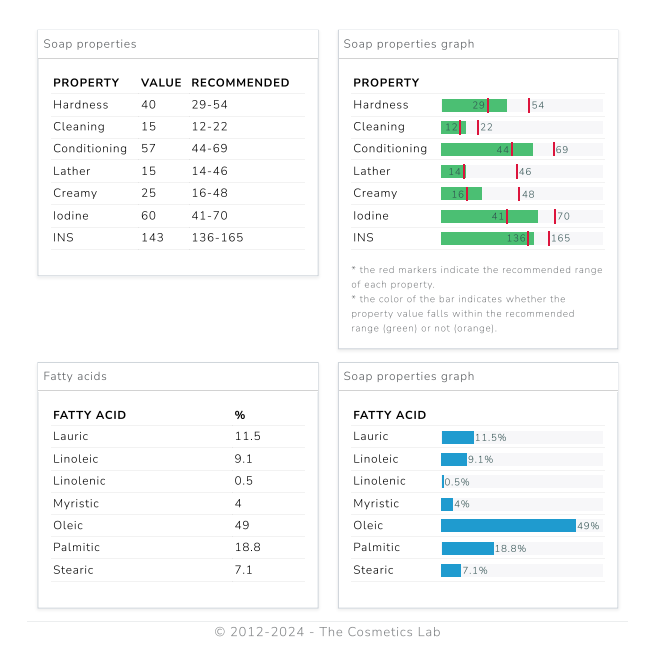

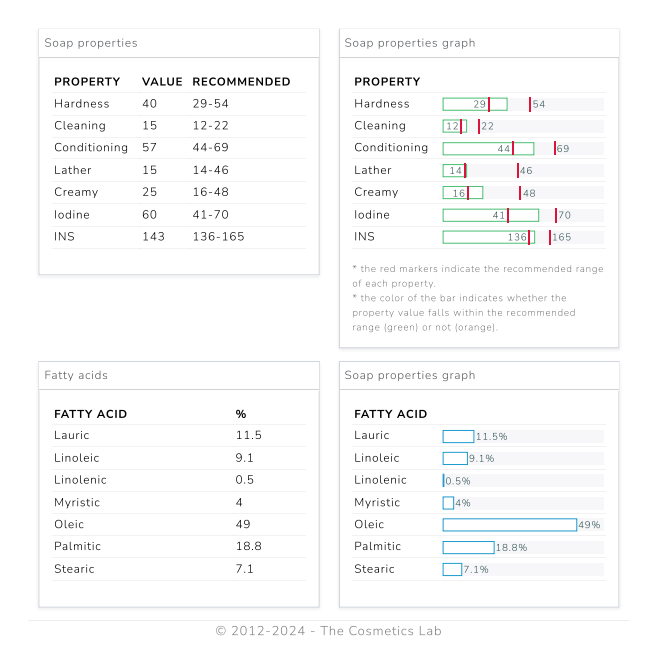

The images below illustrate the difference between normal printing and ink-saving mode.

Normal print mode

Ink-saving print mode

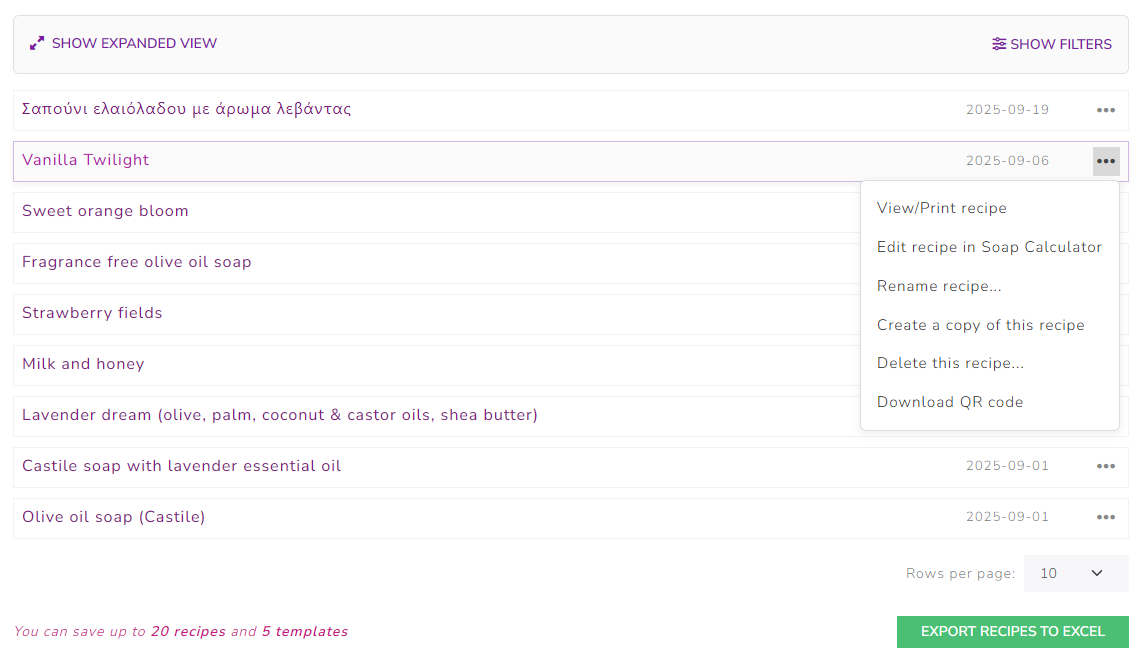

Managing your recipes

To manage your recipes, go to the User menu and select [My recipes]. In the recipe management page you can:

- View a recipe

- Edit a recipe (open it in the Soap Calculator)

- Create a copy of a recipe

- Rename a recipe

- Delete a recipe

- Download QR code of a recipe

We have prepared a short video which describes all the functionality available in this page, here:

Soap recipe management made simple

On this page, you’ll see all your recipes, with the most recently edited ones appearing first. Here's what you can do:

- You can click on any recipe to expand it and view its properties and ingredients.

- For soap properties, numbers in orange indicate values outside the recommended range, while green numbers show values within range.

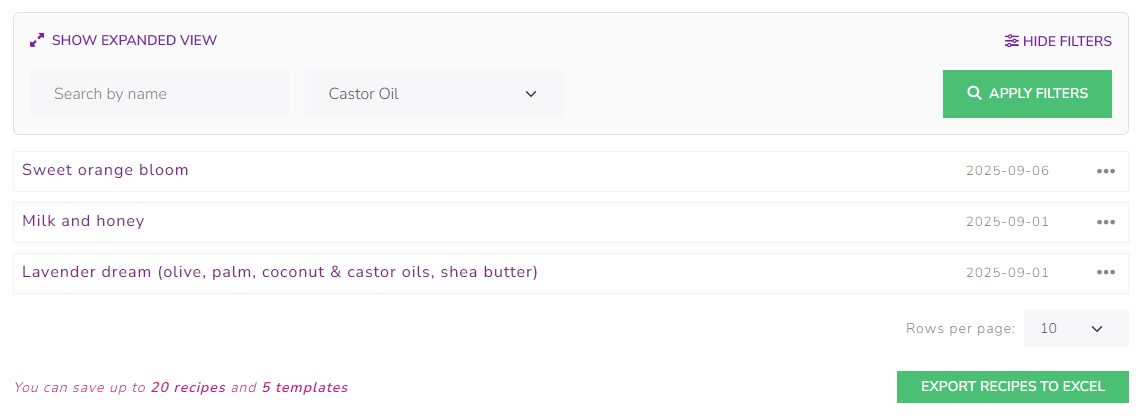

- Instead of opening each recipe one by one, you can click the “Show Expanded View” button to expand all recipes at once. This makes it easy to see all properties and ingredients at a glance. Click “Compact View” to collapse all recipe rows.

-

Filtering is also available. Click “Show Filters” to search either by recipe name or by ingredient.

- Type all or part of an oil name and press ENTER (or click "Apply filters") to show oils containing the text you typed.

- Choose an ingredient from the list to display only the recipes that contain it.

- For each recipe, additional options are available from the ellipsis button on the right. Available options are: edit / view / rename / create a copy / delete / download QR code.

- Last but not least, you can export all your recipes into a single Excel file. This feature can be used either to create a backup of your recipes, or as a template for your batches.

Using QR codes

Once saved, each recipe has a unique QR code which you can download or print.

- To download a QR code, go to recipe management (User menu / My recipes). Click the ellipsis button on the recipe you want and from the drop down menu select "Download QR code".

- To print a QR code, all you have to do is check the "Print barcode" checkbox in print options. After that, the QR code will be printed next to the recipe name in the printout.

- When you scan a printed QR code, you are directly taken to the Soap Calculator to edit your recipe.